Modél Penukar Panas Permukaan Kerok SPSV Supplier Cina

Produsen sareng Supplier Penukar Panas Permukaan Kerok Cina, Votator & Perfector. Perusahaan kami ngajual Penukar Panas Permukaan Kerok Cina, Votator & Pefector, wilujeng sumping ngahubungi kami.

Aplikasi

Penukar panas permukaan kerok séri SPSV (Super Votator) dirancang khusus pikeun industri pangan viskositas tinggi, khususna cocog pikeun produsén pangan margarin puff pastry, margarin méja, sareng shortening. Alat ieu ngagaduhan kapasitas pendinginan anu saé sareng kapasitas kristalisasi anu saé. Alat ieu ngahijikeun sistem pendingin kontrol tingkat cairan Ftherm®, sistem pangaturan tekanan penguapan Hantech, sareng sistem pengembalian minyak Danfoss. Alat ieu dilengkepan struktur tahan tekanan 120bar salaku standar, sareng daya motor maksimum anu dilengkepan nyaéta 55kW, cocog pikeun produksi produk lemak sareng minyak anu kontinyu kalayan viskositas dugi ka 1000000 cP.

Mesin Kompetitif Anu Sarupa

Pesaing internasional SPSV SSHE nyaéta séri Perfector, séri Nexus sareng séri Polaron SSHE di handapeun gerstenberg, séri Ronothor SSHE ti perusahaan RONO sareng séri Chemetator SSHE ti perusahaan TMCI Padoven.

Spésifikasi Téknis

| Seri Super Votator | SPSV-16/1 | SPSV-16/2 | SPSV-16/4 | SPSV-18/1 | SPSV-18/2 | SPSV-18/4 |

| Kapasitas Nominal Margarin Puff Pastry @ -20°C (kg/jam) | Teu aya | 1150 | 2300 | Teu aya | 1500 | 3000 |

| Tabel Kapasitas Nominal Margarin @-20°C (kg/jam) | 1100 | 2200 | 4400 | 1500 | 3000 | 6000 |

| Pangurangan Kapasitas Nominal @-20°C (kg/jam) | 1500 | 3000 | 6000 | 2000 | 4000 | 8000 |

| Jumlah sirkuit Refrigeran | 1 | 2 | 4 | 1 | 2 | 4 |

| Jumlah Tabung per sirkuit Refrigeran | 1 | 1 | 1 | 1 | 1 | 1 |

| Motor pikeun Margarin Puff Pastry (kw) | Teu aya | 22+30 | 18.5+22+22+30 | 37+45 | 30+37+45+55 | |

| Motor pikeun Margarin Méja (kw) | 18.5 | 18.5+18.5 | 18.5+18.5+22+22 | 30 | 22+30 | 22+30+37+45 |

| Motor pikeun Shortening (kw) | 18.5 | 18.5+18.5 | 18.5+18.5+22+22 | 30 | 22+30 | 22+22+30+30 |

| Jumlah Kotak Gir | 1 | 2 | 4 | 1 | 2 | 4 |

| Beungeut Pendingin per Tabung (m2) | 0.61 | 0.61 | 0.61 | 0.91 | 0.91 | 0.91 |

| Spasi Anular (mm) | 10 | 10 | 10 | 10 | 10 | 10 |

| Kapasitas @ -20°C (kw) | 50 | 100 | 200 | 80 | 160 | 320 |

| Tekanan Kerja Maks. @ Sisi Media (Bar) | 20 | 20 | 20 | 20 | 20 | 20 |

| Tekanan Kerja Maks. @ Sisi Produk (Bar) | 120 | 120 | 120 | 120 | 120 | 120 |

| Suhu Gawé Min. °C | -29 | -29 | -29 | -29 | -29 | -29 |

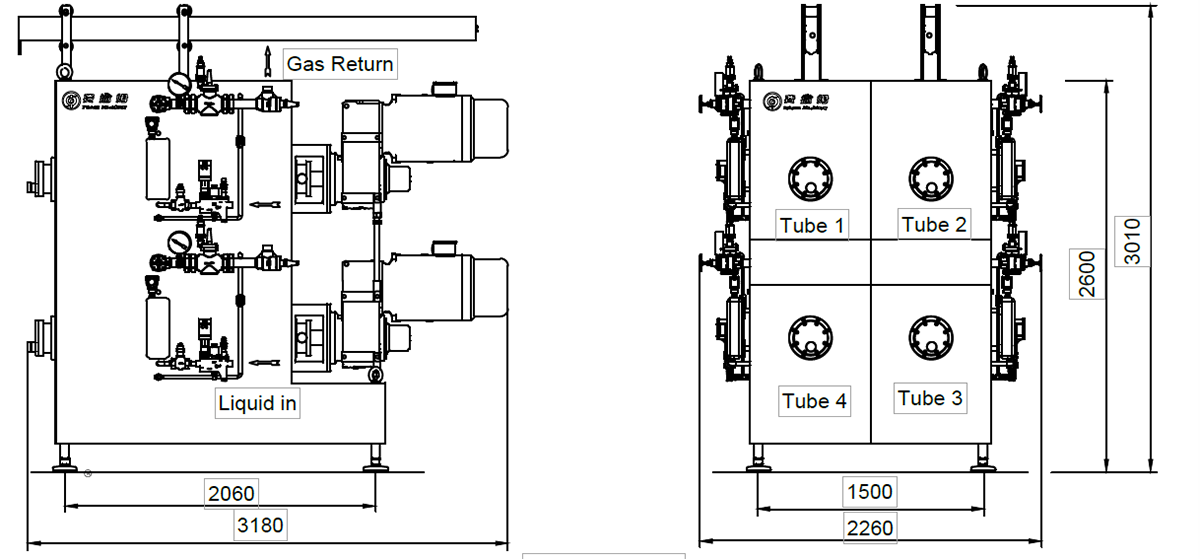

| Diménsi Tabung Pendingin (Diaméter/Panjang, mm) | 160/1200 | 160/1200 | 160/1200 | 180/1600 | 180/1600 | 180/1600 |

| Volume Produk per Tabung (L) | 8.6 | 8.6 | 8.6 | 10.5 | 10.5 | 10.5 |

| Pipa Produk Asupan/Output (mm) | DN50 | DN50 | DN50 | DN50 | DN50 | DN50 |

| Baris-baris Scraper | 4 | 4 | 4 | 4 | 4 | 4 |

| Laju Rotor Scraper Nominal (rpm) | 340 | 340 | 340 | 240 | 240 | 240 |

| Kapasitas Temperasi Cai (kw) | 6 | 6+6 | 6+6+6+6 | 6 | 6+6 | 6+6+6+6 |

| Volume Atemperasi Cai (L) | 30 | 30 | 60 | 30 | 30 | 60 |

| Pompa Sirkulasi Cai (kw) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

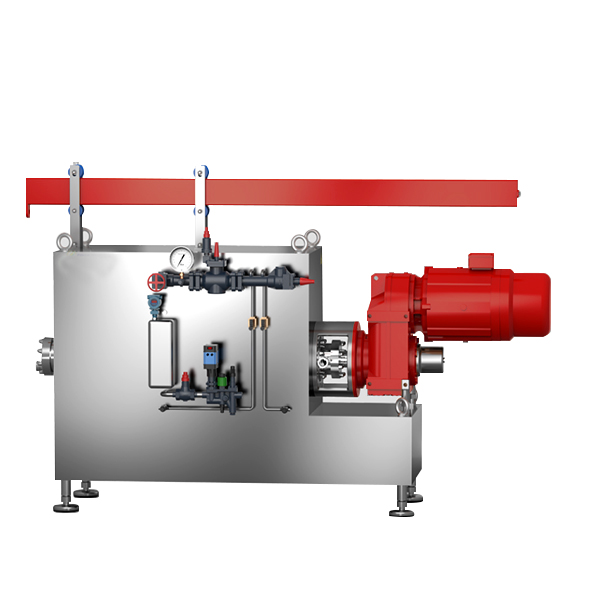

Gambar Peralatan

Komisioning Situs